What engineer-to-order means and how ETO projects are managed

28 Jan, 2026

Key products for the key industries are often not ready-made. They only exist after a customer explains exactly what they need. Engineer-to-order, often called ETO, is the production approach used for these situations. Each product is designed and built specifically for one customer, based on their unique requirements.

ETO is used when standard products or predefined options are not enough. It is common for complex, technical, or one-off products where precision matters more than speed. Nothing is produced in advance. Every project begins with a customer order.

What engineer-to-order means

Engineer-to-order means that engineering work starts after the order is placed. The product is not assembled from existing designs but created from scratch. Design, engineering, purchasing, and production are all part of the same project flow.

Because every order is different, ETO projects usually take longer and require more planning. Each order is managed as its own project, with its own timeline, budget, and technical scope.

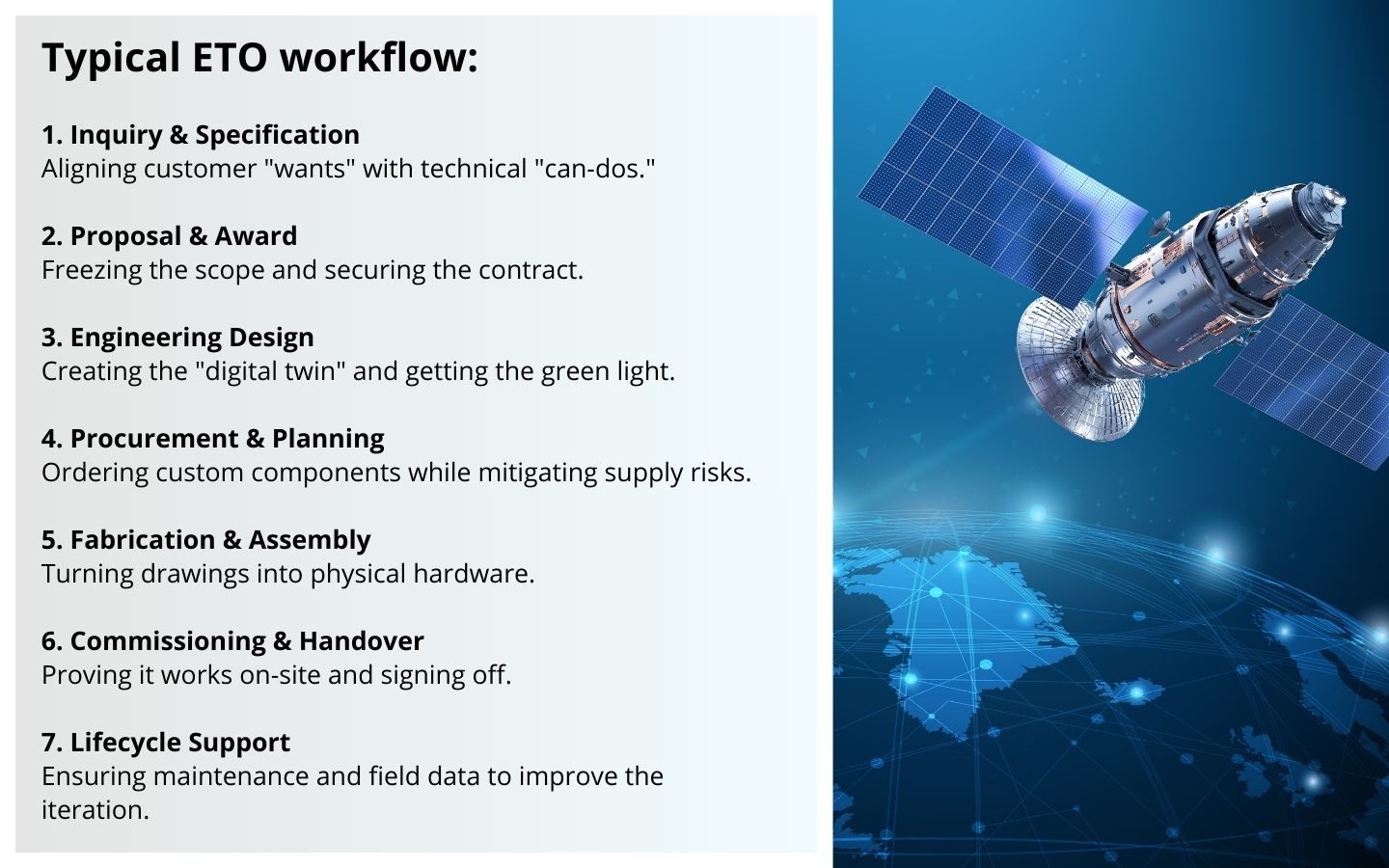

The engineer-to-order project workflow

Engineer-to-order projects do not follow a fixed sequence and are often shaped by the customer’s needs, experiences, expectations, and contractual approach. The phases involved may vary in depth and overlap based on client input. Despite these differences, ETO projects typically move through a set of recurring stages.

How engineer-to-order differs from configure-to-order

While buying stocked products is easier to differentiate from engineer-to-order, and the cheapest option. Configure-to-order is more closely related to engineer-to-order. There are some key differences, though. Configure-to-order uses existing designs and modules, allowing customers to choose from predefined options only. This keeps lead times shorter, products cheaper, and limits engineering time. With engineer-to-order there is pretty much a complete new design. Engineers are involved in every part, lead times are longer, and the result is fully customised. This makes engineer-to-order better suited for specialised products where standard configurations cannot meet the requirements.

| Feature | ETO | CTO |

|---|---|---|

| Lead time | Longer | Shorter |

| Sales process | Complex, consultative | Streamlined |

| Involvement of engineering | Required for every order | Limited to standard configurations |

| Design freedom | Fully customer-specific | Limited to pre-developed modules |

The hybrid approach

A hybrid approach is commonly used in practice, where some parts of the product are engineered to order while others are configured to order. Custom satellites are a good example of this. The overall satellite mission, payload configuration, and performance requirements are engineered specifically for each customer, while subsystems such as onboard computers, power units, reaction wheels, or communication modules are often selected from pre-qualified, configurable “building blocks”.

Benefits and disadvantages of engineer-to-order

Engineer-to-order offers clear benefits, but it also comes with challenges. The main advantage is flexibility. Customers receive a product tailored exactly to their needs, which often leads to higher satisfaction and stronger long-term relationships. ETO also allows companies to compete on expertise rather than price alone.

The disadvantages are time, costs, complexity, and risk. ETO projects take longer, cost more to manage, need more manpower and resources, and are harder to predict. Mistakes can be expensive, and standardisation is limited. For many businesses, ETO makes sense only when the value of custom work outweighs these challenges.

The need for an ETO management system

A proper system to manage an ETO process is extremely important. Customers and engineering teams need to be able to communicate properly and ensure that any content and communication shared is clearly defined, traced, and used to its full benefit to the project. Reasons you need a good system are:

- To keep customer requirements, decisions, and changes aligned throughout the entire project

- To support effective collaboration between customers, engineering teams, project/program managers, and suppliers

- To manage uncertainty and change without losing control over scope, cost, and schedule

- To ensure traceability and accountability for all technical and project decisions

- To provide clear visibility into project status, risks, and priorities for timely decision-making

Managing ETO projects

As discussed before, engineer-to-order projects progress through a series of phases that transform an inquiry into a engineered solution. Each phase of this process has specific risks, from unclear requirements and technical feasibility to execution quality and long-term performance. While the process must remain flexible to accommodate change, control is maintained through dedicated management disciplines that structure decision-making, traceability, and execution across the lifecycle.

Inquiry and requirements definition

The lifecycle begins with capturing and clarifying customer requirements. Requirements Management supports this phase by translating customer needs into a structured technical and commercial scope that can be assessed for feasibility. Functional expectations, performance targets, constraints, and assumptions are discussed and formalised before engineering work begins.

These requirements form the baseline for all subsequent decisions. As feasibility studies and early trade-offs are performed, requirements are refined while maintaining traceability, ensuring that evolving solutions remain aligned with customer intent and agreed scope.

Concept development and technical definition

During concept development, initial solution ideas are evaluated and shaped into feasible engineering concepts. Customer requirements are analysed, high-level architectures are defined, and early trade-offs are performed to balance performance, cost, schedule, and risk. At this stage, designs remain flexible as uncertainties are progressively reduced.

As the selected concept evolves into detailed engineering, Document and Configuration Management becomes essential. Specifications, drawings, calculations, and technical data are created, revised, and approved in a controlled manner, ensuring that engineering, procurement, and production activities are always based on consistent and authorised information.

Formal reviews and stage-gate control

Formal reviews structure the progression of the engineer-to-order lifecycle. Review Management supports key milestones such as concept reviews, preliminary and critical design reviews, and customer acceptance points. These reviews assess technical maturity, verify compliance with requirements, and confirm readiness to proceed to the next phase.

Review outcomes frequently result in actions. Structured tracking and traceability ensure that findings are addressed and closed before further commitments are made.

Continuous risk identification and mitigation

Uncertainty is inherent in engineer-to-order projects. Risk Management is therefore applied throughout the lifecycle, beginning in early concept phases and continuing through execution. Risks related to new designs, supplier dependencies, cost exposure, and schedule are identified, assessed, and actively mitigated to prevent issues from escalating later in the project.

Manufacturing, integration, and deviation handling

During manufacturing, integration, and testing, the focus shifts to execution and compliance. Custom designs and first-of-a-kind solutions often result in deviations from specifications or unexpected issues. Non-Conformance Management supports the controlled assessment, approval, and resolution of these deviations, protecting quality, safety, and compliance while keeping the project moving forward.

Industries where engineer-to-order is commonly used

ETO is most common in industries where standard products cannot meet technical or operational demands:

- Aerospace: Specialised components and systems requiring precision, certification, and tailored design.

- Heavy machinery: Custom presses, production lines, and factory machines built for specific processes or spaces.

- Construction: Bridges, tunnels, and large technical installations designed for unique locations and loads.

- Transportation: Rail vehicles, ships, and purpose-built trucks with customer-specific performance requirements.

- Industries: Custom reactors, piping systems, and treatment plants built around specific materials and safety needs.

How ECLIPSE Software Suite supports ETO projects

Engineer-to-order projects succeed when flexibility is matched with control. Managing changing requirements, complex engineering data, risks, and deviations across a long project lifecycle requires a structured and connected way of working. With the right foundation in place, organisations can maintain alignment between customer intent and execution, respond to change with confidence, and deliver complex, one-off products with predictability, quality, and control.

Desmond Gardeslen

Product Marketing Manager

Passionate about the intersection of space technology, marketing, business, engineering, and innovation.