Non-Conformance Report: Everything You Need to Know

12 Jan, 2025

In many engineering organisations, when a Non-Conformance is identified, a Non-Conformance Report is created. Non-Conformances occur when a product, service or procedure does not meet the initial quality regulations or requirements defined by the standards set. They can appear in any department of your organisation, including activities, operations, processes, and production. To manage Non-Conformances properly, a Non-Conformance Tracking System is often used. This article discusses Non-Conformance Reports and how they contribute to better quality management.

What is a Non-Conformance Report?

A Non-Conformance Report (also known as a Non-Conformity Report or NCR) is a document that identifies and reports any discrepancies between the actual condition of a product, service or process and the requirements defined by quality standards. Non-Conformance Reports can be generated for any area of an organisation but are most commonly associated with manufacturing, production and operations.

The NCR is a well-organised document that reports the specific Non-Conformity found to understand the underlying threat imposed for violating the requirements and enables someone to take subsequent actions. Furthermore, the NCRs help to create a regulatory plan of action to prevent it from happening again and assist future compliance and audits.

By creating an NCR, the issue(s) can be defined, analysed, and audited to be fixed correctly and ensure the conformity will be dealt with and meet the safety and quality measures set.

A Non-Conformance Report documents the details of a Non-Conformance identified in a structured way. Accordingly, organisations, projects, or people who do not meet the quality and safety standards can be held accountable for not following the requirements.

Want to make Non-Conformance Management easier, faster, and more structured?

Try the ECLIPSE Software Suite

Types of Non-Conformance Reports

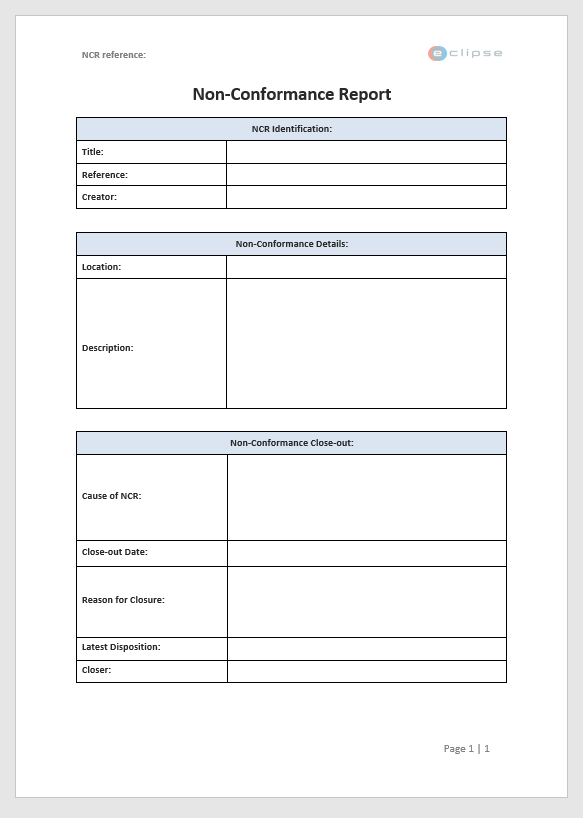

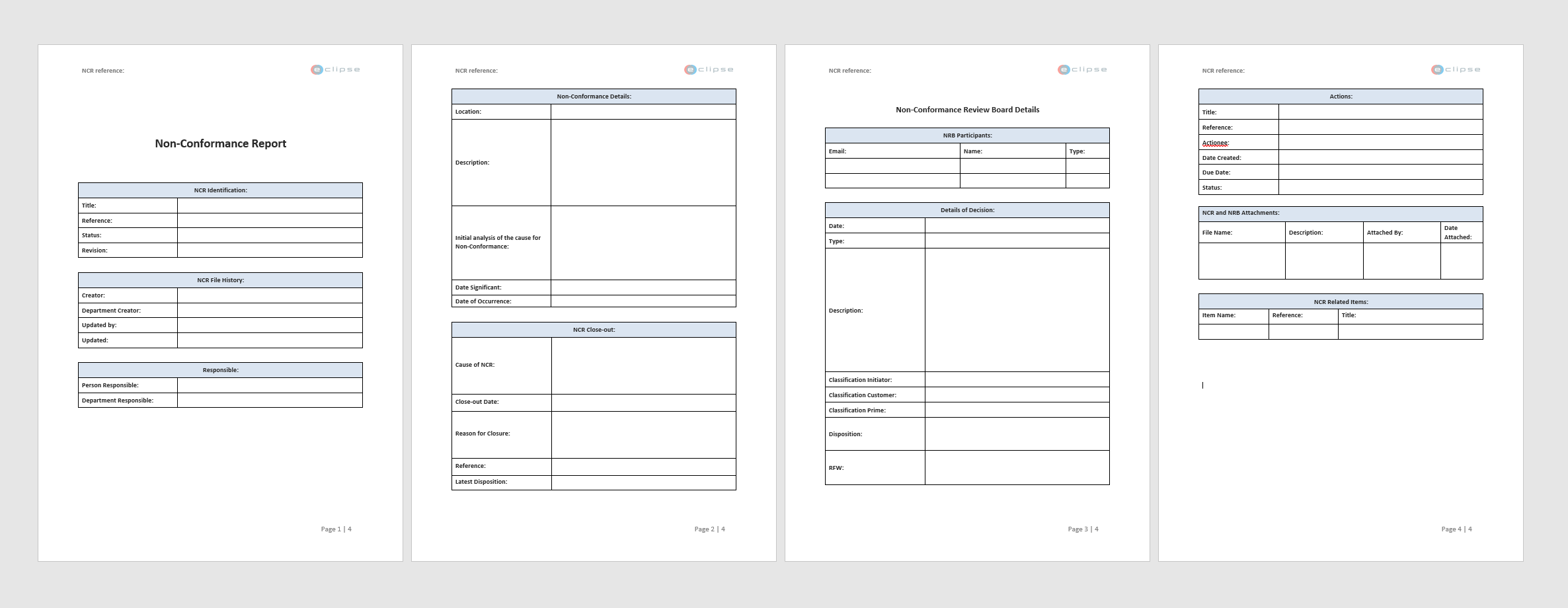

Non-Conformance Reports are typically customised and standardised for an organisation. In other words, an organisation will choose to create a Non-Conformance Report (or several) that fits the need. With a Non-Conformance Report Software, you can easily create several types of documentation that are fit for purpose, while also having the information in an orderly software environment. Below we have a Simple and Complex Non-Conformance Report Template.

Simple Non-Conformance Report

Smaller organisations might choose to have a simple one-page non-conformance report without information on details, actions and responsibilities.

Extensive Non-Conformance Report

Larger organisations and ones working with compliance will typically need a more extensive report.

The information inside of Non-Conformance Reports

Organisations can customise Non-Conformance Reports to fit their specific organisational needs. For example, they can add checkboxes and text fields to the Report to capture detailed information about each Non-Conformance.

An example of information you can find within a Non-Conformance Report is

- Date and time of the occurrence

- Department of Non-Conformance

- Identification number (reference)

- Identifer of the Non-Conformance

- Person responsible

- E-signature of the person completing

- Initial analysis of the Non-Conformance

- Cause of the Non-Conformance

- Date of Non-Conformance

- Location of the Non-Conformity

- Description of the Non-Conformity

- Corrective and preventive actions

- Significant

- Classification of minor or major

Because Non-Conformances can be reported in various departments, there are multiple types of Non-Conformance Reports. Having a structured template for each department helps maintain the quality control system, so no information is missed.

Minor and Major Non-Conformance Reports

In general, a Non-Conformance is considered Minor or Major based on the severity and impact of the Non-Conformance.

Minor Non-Conformance

A minor Non-Conformance Report is less severe and has a lower impact on the product, service or process. The corrective action for a minor Non-Conformance is usually easy to implement and does not require significant product, service, or process changes. Minor Non-Conformance can be considered small events and small slip-ups that are easily correctable. Examples of these are:

- Unauthorised document alteration

- Isolated personnel incident

- One missing document from a series

- Slightly out-of-tolerance measurement

- Use of unapproved equipment

Dealing with a minor Non-Conformance is usually straightforward as the corrective action required is not extensive. For example, if a machine was used that was not on the approved list, the corrective action may be as simple as updating the list of approved machines or using a different machine in future.

Major Non-conformance

Major Non-Conformances are violations that require communication up the management chain as they have a significant impact on the product, service or process. Multiple and huge violations of requirements include:

- Unauthorised alterations of documents

- System-wide personnel incident

- Multiple missing or unsigned documents

- Not meeting critical performance specifications

- Processes out of control

Here, the corrective action is likely to be more complicated and extensive and may require significant product, service, or process changes. The expectation is that major Non-Conformances will impact the whole project. Therefore informing all parties (teams and organisations) involved on time is essential.

Why use Non-Conformance Reports?

Businesses may utilise non-conformity reporting to guarantee that established standards pass-through reporting. The benefits of reporting Non-Conformances can include:

1. Improvement of product and services

Non-Conformance Control is critical for improving your products and services since it will reveal whether you are complying with the client’s specifications or your own.

Non-Conformance Reports help you find and fix problems with your products and services. Furthermore, by filling out a Non-Conformance Report, you can take the necessary steps to avoid making the same mistake again in future.

2. Prevention of customer complaints

When customers complain, they have received a product or service that does not meet their expectations. Non-Conformance Reports help businesses to identify potential customer complaints and prevent them from happening.

3. Reduction of operational costs

By identifying and correcting problems early, businesses can avoid the cost of rework, scrap, and waste. Non-Conformance Reporting can also help companies to avoid the cost of customer complaints and lost business.

Furthermore, you will waste less money in operations if the decision is made on the Non-Conformance not to fix or maintain technical requirements. Transparency and communication are vital in ensuring that all stakeholders are updated and aware of the situation.

4. Improvement of efficiency

By addressing problems early, businesses can improve the efficiency of their operations. Non-Conformance Reports can help companies to identify and eliminate bottlenecks and streamline processes.

Through a Non-Conformance tracking system, you can efficiently communicate, track, and manage the status of each Non-Conformance throughout the entire process from discovery to closure. This will help ensure that corrective and preventative actions are on time and that the root cause of the problem is identified and addressed.

5. Prevention of reoccurrence of non-conformities

Non-conformity reports help identify the root causes of non-conformities and prevent them from happening again. This can improve the quality of products and services and the efficiency of operations.

When someone needs to write a report on an issue that has arisen, they will be less likely to make the same mistake twice if they have a clear understanding of what went wrong and why. By implementing a Non-Conformance reporting system, you can help to ensure that lessons are learned from mistakes and that the quality of your products and services is improved.

6. Compliance with regulatory requirements

Many businesses must comply with regulatory requirements (ISO, ECSS, AS9100, etc.) that mandate the reporting of Non-Conformances. By complying with these requirements, businesses can improve their image and demonstrate their commitment to quality.

The specific requirements will vary depending on the location and type of business. Whether you are working in aerospace, space or telecommunication, most legal systems require some form of Non-Conformance reporting as part of regulatory compliance.

7. Improve communication

Effective communication is essential for the smooth running of any organisation. Non-Conformance Reports can help to improve communication by ensuring that information about problems and their resolution is shared between all relevant parties.

Improved communication and coordination between departments will help to avoid the duplication of effort and the waste of resources. Requirement issues arising in one department can be communicated to other departments to be considered in the development process.

8. Optimisation of ROI

When reporting on Non-Conformances throughout the organisation, such as time, people, tools, manufacturing, operations, productions, etc., it allows you to track impacts on other departments, customers, and the business as a whole.

Issues arising that will have a serious impact on the products or service quality will be dealt with by the Non-Conformance board. In this manner, they ensure that the return on investment is maximised.

How to manage Non-Conformances Reports

The management of Non-Conformances is done by creating Non-Conformance Reports and notifying Non-Conformance Boards.

The Non-Conformance board will have to deal with the product or service that doesn’t meet the requirements. Options include:

- Scrap – The product is discarded and is no longer used.

- Rework – The product is sent back to be fixed to meet the requirements.

- Regrade – The product is downgraded so it can still be used, but it doesn’t meet the requirements.

- Repair – The product is fixed, so it meets the requirements.

- Do nothing – The product is used as it is, even though it doesn’t meet the requirements.

Non-Conformance boards consist of different people from different parts of the company who will work together to fix the product. The management of Non-Conformances can be a complex and time-consuming task. Businesses can use software that automates the creation, assignment, and tracking of Non-Conformance Reports to streamline the process.

Non-Conformance reporting software can help businesses to:

- Save time

- Improve communication

- Avoid duplication of effort

- Reduce the risk of human error

- Improve the management of Non-Conformances

Want to make Non-Conformance Management easier, faster, and more structured?

Try the ECLIPSE Software Suite

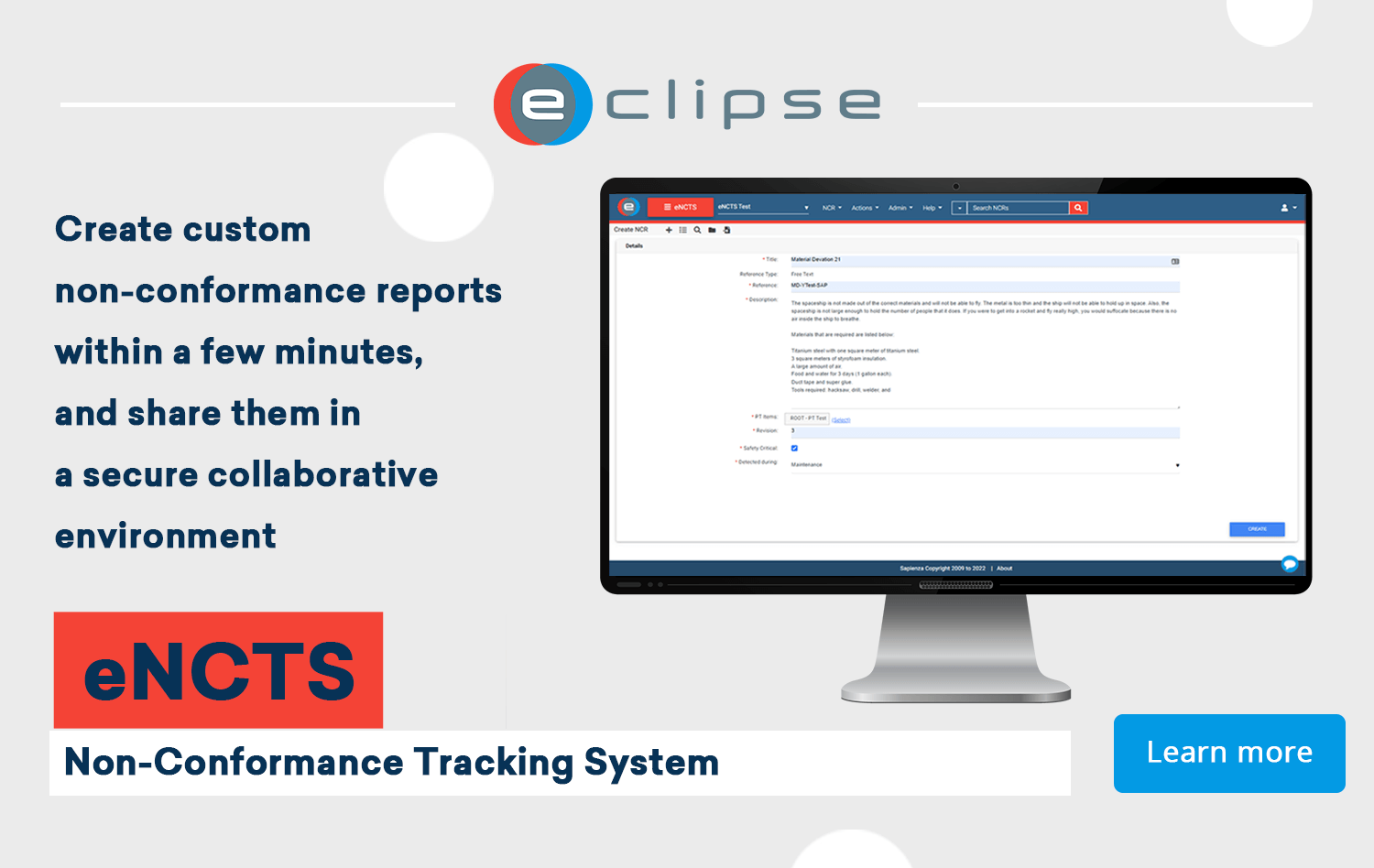

ECLIPSE Non-Conformance Tracking System

The ECLIPSE Non-Conformance Tracking System (eNCTS) can help businesses manage non-conformances. It provides a centralised system for all Non-Conformance Reports and automates templates, non-conformance boards, notification, and tracking of non-conformances.

With the other modules, ECLIPSE can offer a complete solution for quality management. Contact us for a free demo and learn more about how we can help you manage non-conformances in a compliant way.